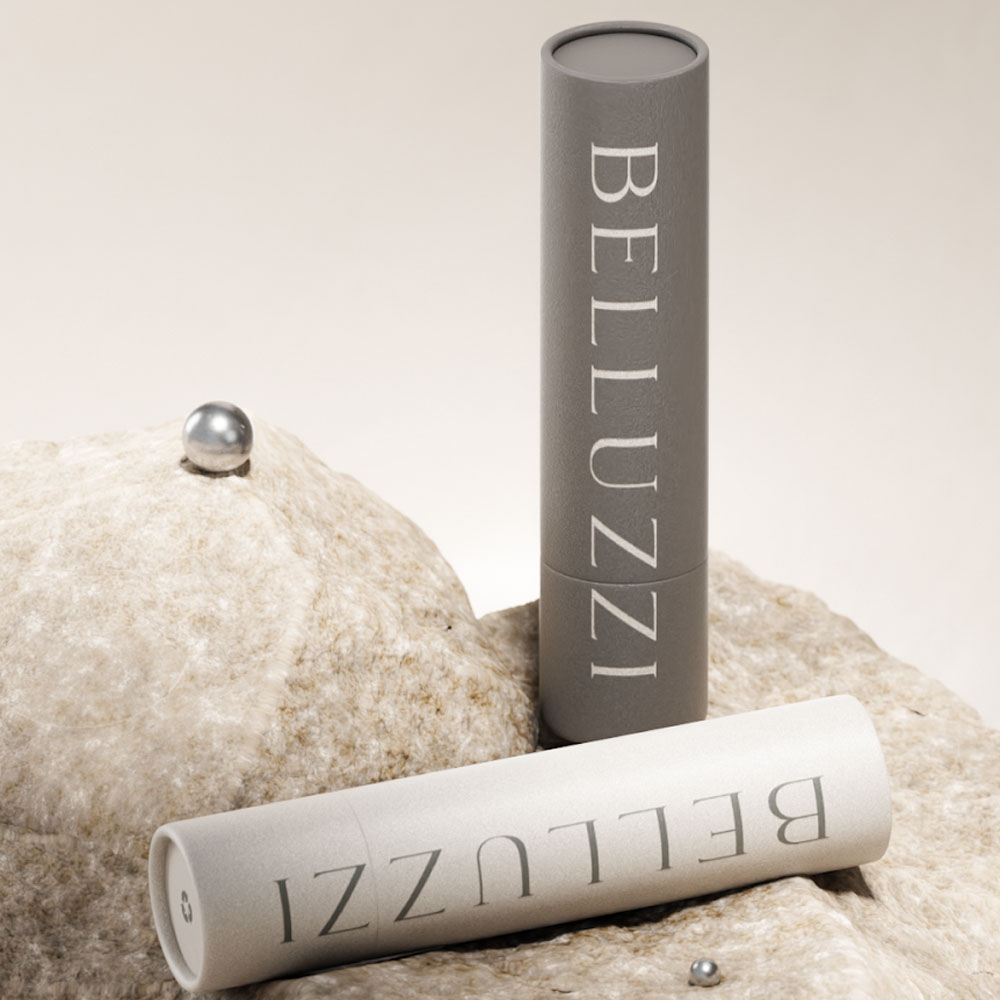

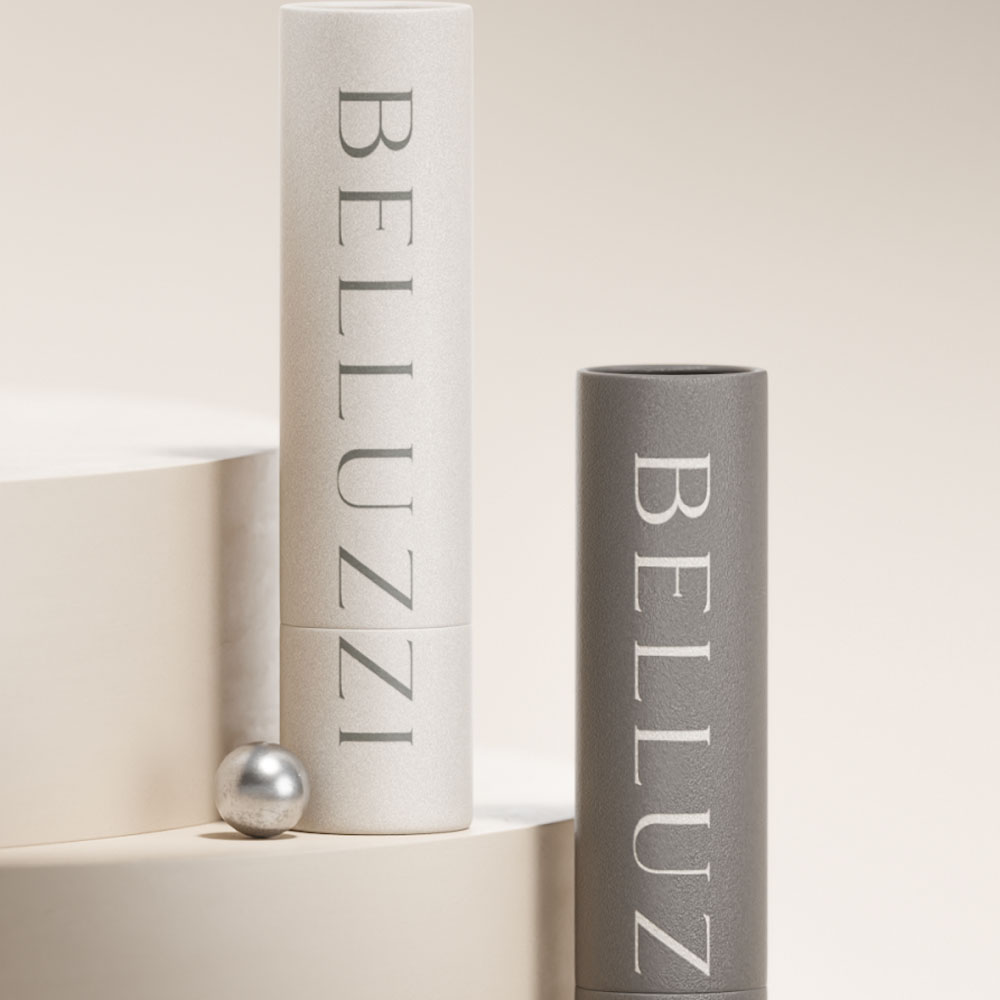

Paper tube manufacturers use different paper core tubes in the production process of industrial paper tubes. The key is high tensile strength, which is widely used in paper industry, plastic film and other large and medium-sized rewinding machines. High-strength paper core tubes; thin and thick walls , the length is accurate, suitable for small-wall thick paper core tubes in the fields of plastic wrap paper tubes, diagnosis and treatment, etc.; accurate net weight, high-strength paper tubes, high quality, suitable for spandex silk paper core tubes used in rewinding machines such as spandex yarn; Iron headed paper core tubes required for cash flow and recycling applications.

Waterproof paper tube has certain application advantages in application, which is incomparable with many general paper tubes. Waterproof paper tube has certain process performance, porous structure and air permeability. It has good storage properties and can be stored at room temperature for more than 3 months regardless of level. The waterproof paper tube has good cold resistance, and it is not easy to suffer the harm of the weather in the application process. The tensile strength, water resistance and cold resistance of the paper tube are superior to those of the paper tube produced by other rubber seeds. The paper tube is more environmentally friendly in the process of storage and application, the paper tube glue used in the production process is more healthy in body and mind, the drying effect of the product is very good, and the speed is faster.

English

English Español

Español Português

Português Pусский

Pусский Français

Français Deutsch

Deutsch 日本語

日本語 한국어

한국어 Italiano

Italiano عربى

عربى